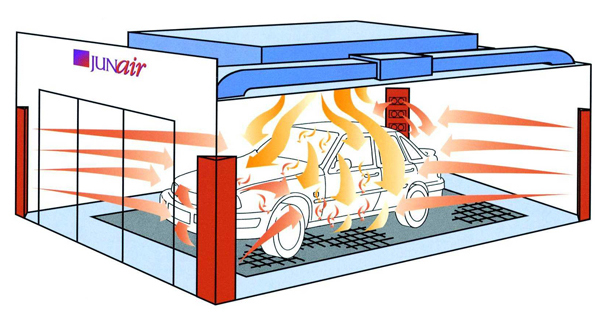

The Junair Americas 5 Series spray booth oven is a highly specified production unit. Every feature of this spray booth has been engineered to be the best in its class. Combined with energy saving and production enhancing equipment the 5 Series spray booth oven delivers the highest quality paint finish at the lowest cost per unit. A LEVAC or EVAC fully extracted and balanced floor is incorporated into the 5 Series spray booth oven as standard. In combination with the full width, full length plenum, the downdraft airflow through this cabin is second to none. Incorporating a full range of highly innovative features including: T-5 high output lighting; the best "fit and finish" cabins in the industry; the latest in controller technology; energy savings at all levels and the QADs™ air movement system as standard, the Junair 5-Series booths will provide your shop substantial reductions in energy costs.

See more - visit Junair 5 Series

The QADs System creates a "convection oven" atmosphere, equalizing the temperature throughout the entire booth, providing consistent metal temperatures for an optimal waterborne refinish environment. QADs feature the patented Intake Plenum Air Acquisition System, providing heated filtered air that ensures clean air during the paint drying process. The QADs System interfaces with the bake cycle of the existing air make up unit to create more air turbulence, leading to shortened cycle times in both flash and bake. Tremendous fuel and energy savings are attained. QADs™ is the only auxiliary air movement system that draws air from the spray booth plenum. ‘QADs™ Automatic’ and ‘QADs on Bake’ models have doors that operate automatically on the blower towers, which are closed during the spray cycle to protect the blower nozzles from overspray. These patented technologies prevent dirt and overspray from being blown on the waterborne basecoat during the flash off cycle, or the clear on the bake cycle! Save time, energy and money on paint drying and curing, process more vehicles and generate more revenue.

Smartair is a highly mobile, easy to use, at source extraction system designed to free up your spray booth and maximize your throughput. Spray-Tech/Junair’s Smartair is a mobile painting system that is ideal for smaller spot repairs. Repairs can be refinished quickly, without the need for moving the vehicle or full masking.

See more - visit Mobile Repair Unit

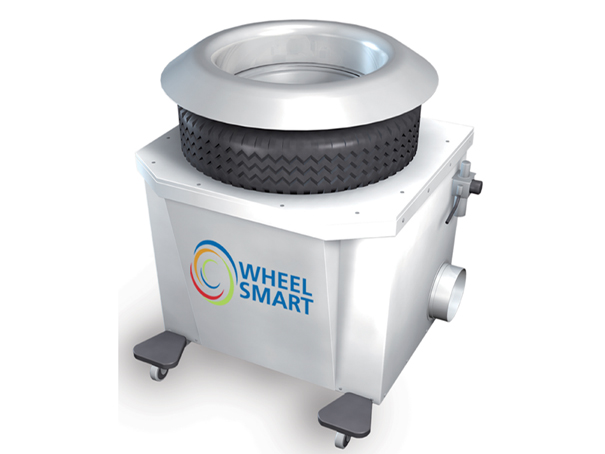

Wheelsmart is an at source extraction system, which allows the paint finishing process of wheels to be carried out in workshops without the need for a conventional spray booth. Wheelsmart uses the extraction system from the Junair Smartair unit and creates a mobile wheel painting facility in the workshop that meets NESHAP 6H and other local codes.

See more - visit Wheel Refinishing System